Waiting for delivery

Over the last 2 years most of us have experienced longer waiting time than ever for orders to arrive. Product shortages often deprived many of us our first-choice brands, forcing us to look for a substitute option. To better understand this situation, we need to think back to the beginning of the pandemic, which highlighted the weaknesses of the supply chain and led to its disruption.

When lockdown restrictions hit stores, businesses and offices in early 2020, plenty of factories reduced their manufacturing output and capacity via forced redundancies. Transport companies followed a similar pattern, as they assumed limited demand for services. China, the world's leading exporter of goods, focused on manufacturing of protective accessories, mainly face masks, delivering more than half of the global demand. On the other hand, contrary to initial pandemic-era expectations, order volume of IT products (laptops), electronics goods and furniture increased considerably and the industry did not manage to keep pace with this roaring demand. The world’s factories faced workforce shortages and a lack of raw materials and key components, including famous auto chips. As for maritime transport, which is estimated to account for around 80% of global trade, shipping delays caused congestion in major ports across the world. All this triggered the ongoing global supply chaos, which is seemingly still increasing. Product shortages are affecting almost all industries, from the automotive sector, electronics and furniture industry to building supplies. In addition, as demand continues to increase, shortage of shipping containers has led to drastic inflation of shipping cost; for example, shipment of goods from Shanghai to Los Angeles has increased tenfold. And the story does not end here. The latest outbreak of the pandemic in China has again caused extensive factory closures and reduced truck traffic across the country, while the sanctions against Russia mean that railroad shipments from Middle Kingdom to Europe, amounting to millions of containers, must also be shifted to the sea. The war in Ukraine threatens new shortages, including nickel, aluminium, sunflower oil and many other raw materials.

The supply chain is apparently too complex, interconnected and dependent on distant factories to be immune to the disruptions we are experiencing now. To handle the crisis, businesses need to reassess and transform their current manufacturing models and sites. Needless to say, a change of consumer behaviours and purchasing patterns will also be essential to control the chaos, as some products will not be produced at all, and others will not be affordable.

The exhibition "Waiting for Delivery" shows alternative models of transport and innovative solutions that can change existing production processes. It also presents ways to involve more end consumers in the process of product manufacturing. The new reality forces all of us to adjust

Boem

products for home

2020

In times of uncertainty in delivery times, 3D printing may be a solution.

A decade ago, 3D printers were presented as innovative equipment that would offer almost unlimited possibilities. And while today 3D printing technology is being used in different industries, from the aerospace or automotive sectors to the medical field, the reality is that three dimensional printers have still not found their place at our homes. The Czech Boem Studio encourages to change it. It offers a series of homeware products that you can print on a 3D printer at home. All you have to do is order a design from the catalogue of models on the studio's website. This is an ideal solution at times of supply insecurity, because it eliminates the need to store and transport goods to final users. The use of 3-D printing, also known as additive manufacturing, has several key advantages over traditional manufacturing, including reduced lead time and cost and energy saving. The Boem Studio offers a wide range of designs of home decor items, flower vases, plant pots in a variety of sizes, small furniture, lamps and also accessories for children, such as sets of sandbox toys.

Foodbugs

food

2022

Will insects become an alternative to more expensive food.

Ukraine and Russia ranked amongst the top global exporters of sunflower oil, barley and wheat, and the war in Ukraine has caused disruption of the food supply. On the other hand, China and India, the world’s biggest wheat producers, are facing the worst crop conditions ever due to droughts, flooding and heat waves caused by climate change – India has already banned wheat exports for these reasons. All this will soon result in extremely high food prices.

Insects, which are being called the food of the future, could be an alternative. They adapt easily to climate change, consume far fewer resources than livestock, so they could be an attractive alternative to traditional meats, and can also replace cereal products. What is more, edible insects are highly nutritional and rich in protein.

A variety of insect species can be used in the kitchen, as proven by the Foodbugs, a brand which offers not only edible insects and insect-enriched snack bars and granolas, but also cricket flour and protein pasta with crickets.

F*cking Stop Burning Clothes

recycled clothes

2021

Fashion industry produces around 92 million tonnes of textile waste yearly. Shockingly, a lorry-load of used and brand new clothes is burned or buried in landfills every single second. Though no exact figures are available, the practice of fast fashion brands deliberately destroying unsold or returned goods in perfect condition to be able to transport them as waste has become increasingly common.

The Milan Flíček's collection called “F*cking Stop Burning Clothes” was made to draw attention to this serious environmental problem. The Czech designer used end-of-collections fabrics that would otherwise have been destroyed, and invented a technique called fire piping to create an impression and shapes of fire on the garments. The collection was inspired by Jan Palach – a student who, in June 1969, committed an act of self-immolation to protest against the apathy of Czechoslovak citizens towards the intervention of the Warsaw Pact troops.

Hashioki

2021

Chopstick holders that give restaurant leftovers a second life.

The researchers of the Institute for Environmental Protection have shown that almost 5 tonnes of food is wasted in Poland every year. On the other hand, food prices keep going up, and are unlikely to stop, especially as we are going to face serious shortages and food insecurity in the near future. In response to the global food crisis, a Swedish designer Carolina Härdh has found a solution to allow reusing leftover food and give it a second life. Hashioki are chopstick holders made for Vrå, a Japanese restaurant in Gothenburg, from its own food waste. The designer has transformed what we usually think of as leftovers into a material resembling elegant terrazzo.

Härdh ground the oyster shells into pieces of various sizes and combined them with dried bits of kombu – an edible seaweed which is very popular in Japanese cuisine. The mixture was bound together by natural adhesive made from the boiled fish bones and starch sourced from the water used by the restaurant to soak and cook rice. The chopstick holders crafted in this way add a décor touch to the restaurant tables and symbolise the zero-waste philosophy to show the guests that the place cares about food resources and manages them wisely.

Returnable packaging for parcel machines

packaging

Modivo is testing reusable packaging for parcel machines.

The coronavirus pandemic triggered new online shopping patterns and caused e-commerce to accelerate globally at a much faster rate than previous years. 2020 saw a ‘skyrocketing’ increase of online sales. In Poland, the percentage of online shoppers increased by 35; 85 percent of Poles reported making more purchases via the Internet, of which 10 percent declared planning to maintain their newly elevated ecommerce shopping habits in future.

In 2020, 640 million parcels were delivered around Poland. This enormous number of shipments means a massive volume of waste – cardboard or plastic films and wraps, which are tossed in trash. Modivo, a fashion e-commerce platform owned by CCC, and InPost have joined their efforts to show an alternative solution, and are testing eco-friendly reusable packages, each including a return label. The idea is to simplify the returning process and make it smooth and efficient. A return packaging can be placed in any parcel machine, from where it will go to Modivo's warehouse and then to the next customer. Each box can be reused this way up to 10 times.

Compromise

clothes

2016

A small sewing studio making sustainable crafts with recycled materials.

Is it possible to afford new clothes without contributing to gigantic piles of waste produced by the clothing industry? Kompromis [‘Compromise’ in English], a small tailoring atelier based in Warsaw, has proven it is. Kompromis is the quintessence of upcycling. Each piece of clothing designed and made by the atelier is fabricated from recycled materials: woollen blankets, second-hand tablecloths or linen. The philosophy of the brand is to combine traditional craftsmanship and sustainable solutions to give a second life to textiles of good quality

This small tailoring atelier offers a vast range of garments, including dresses, shirts, scarves or jackets, all with unique design and aesthetics. The studio also launched a kid sub-brand – clothes made under the “Kompromiś” label [“Miś” means a teddy bear in Polish], to show that sustainable, eco-conscious fashion does not have to be addressed only to the adults. This Warsaw-based fashion atelier is also involved in making costumes for films and designs for catering facilities – using only recycled materials, of course.

Wypożyczalnia ubranek

sharing economy

2018

Sharing economy for children's clothes.

Children outgrow as many as seven clothing sizes in their first two years of life. Some of the things parents buy for their babies are not even worn, others are put on only a few times and are still in great condition. Such clothes could be reused by other children instead of being sent to a landfill. Now it is possible thanks to an initiative of a German textile retailer Kilenda and its partner Tchibo which have recently launched a children’s clothing rental start-up based on the sharing economy concept.

Kilenda combines the sharing economy model with circular fashion by offering an online clothes rental service. The offer includes clothes for children under three, maternity wear and baby carriers – all items made available by Tchibo and produced in line with the principles of sustainability. The service is available in Germany on the Tchibo Share platform. The clothing rental concept can mean a decline in waste and a more environmentally conscious fashion industry.

Forgo Cosmetics

cosmetics

2020

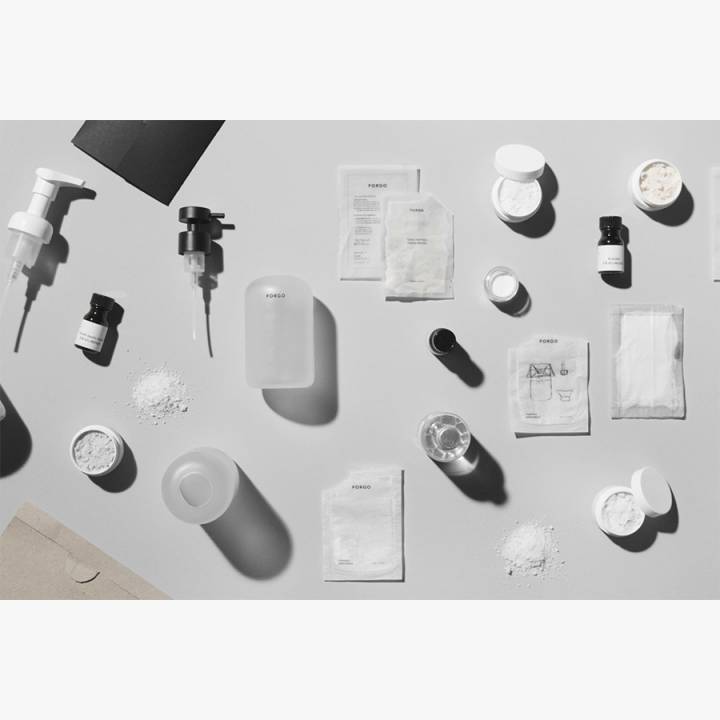

Waterless beauty products in fully dissolvable sachets – you simply need to add water to get a normal quality product.

TerraCycle, a US recycling company, figured out that more than 120 billion pieces of plastic cosmetic packages are produced every year. To reduce these numbers, attempts are being made to replace plastic by other eco-friendly options. And how about revolutionizing the beauty product itself? A solution comes from a Stockholm-based design studio From Us With Love which launched a brand of Forgo sustainable cosmetics coming in paper sachets. Each sachet contains powder which after mixing with water will give us hand soap or shower gel.

Less packaging means reduced greenhouse gas emissions, but apart from ecological aspects, the issue of transport becomes also important. Beauty products packed in paper sachets are lightweight and much more efficient to transport than items containing water which is it’s main ingredient and packed in bottles. Not to mention that all Forgo care products are vegan, purely natural and made only from plant-based ingredients.

SE17 chair

chair

2020

All that was needed to make this chair was some plastic bags and wood from a local park.

Do the things we buy really have to travel around the world before they reach us? Many items are available locally, although we don't always realise it. A group of design graduates from the Royal College of Art have even set their sights on hyper-locality and discovered great potential in materials that many would consider rubbish.

Andreaz Kamolz and Andrew Scott made the “SE17 chair” using only local resources they found in London Borough of Southwark whose postcode is SE17. First, the young designers built an analogue lathe using only wooden pallets and a discarded coat rack, and then used it to create the frame of the chair from wood coming from a nearby park. The chair's woven seat was made from rope which was created from plastic bags gathered at East Street Market. The project not only addresses the supply chain crisis, but is also a step towards increasing self-sufficiency in design.

Buy Back and Resell

2021

With Ikea’s ‘Buy Back and Resell’ service, we can give our old furniture a second life.

In the 1960s, 2 million tonnes of furniture were thrown away each year in the USA. Today, it is estimated to be 12 million tonnes. It is hard to believe, but making furniture has a significant environmental cost. Manufacturing and shipping one piece of furniture generates the emission of close to 90 kg of CO2 – the equivalent of a car trip from Gdynia to Warsaw and back. The good news is that recently, the second-hand furniture market has been booming. The reports say that it will be worth as much as USD 16.6 billion by 2025, which is 70 percent more than in 2018.

No similar research has been conducted in Poland so far. Yet, recent years have seen an increasing number of initiatives to give furniture a second life also in our country. ‘Buy Back and Resell’ programme launched by IKEA is one of the examples. The rules are simple: if you’ ve got an unwanted IKEA furniture that is in relatively good condition, you are now able to sell it back. All you need to do is to fill out the ‘buy back’ estimator form online to get a quote on your old piece of furniture, bring it to your nearest IKEA store and exchange it for a refund card. Then the product goes to the Circular Hub, where it can be bought by a new user at a bargain price.

Parallel Systems

vehicle

2022

Autonomous driverless rail vehicles.

The invention made by Parallel Systems, a company founded by three former SpaceX engineers, may at a first glance look like a typical freight train car. In reality, though, it consists of a shipping container and two autonomous vehicles that are fitted with four wheels, a package of sensors, an electric motor and a battery pack to allow each segment operate autonomously with no need of a locomotive. The segments can also be coupled and may travel in platoons, ideally between 10 and 50 containers according to the inventors.

This is less than for standard freight trains, which have always been long, and have got even longer in recent years. Long trains save on fuel and crew and are cost-effective, but loading and unloading of cargo is time-consuming and may become a real challenge. And they cannot travel on all lines. Pararell Systems believe that their solution is likely to revolutionise the transportation of goods over short distances, saving time and making better use of resources.

PlasticRoad

bike path

A bike path made of recycled plastic is expected to be more durable than a traditional road.

While global production of plastic is dramatically increasing every year, recycling rates are still very low – today only about a third of plastic post-consumer waste is recovered in the EU. KWS, a Dutch business offering infrastructure solutions, has recently launched a new concept that is likely to improve the statistics. The first PlasticRoad bike path based entirely on recycled plastic was opened in the Netherlands. The design’s modular pieces are prefabricated and lightweight, making them easy to move and install. Its permeable hollow structure allows excess water to drain and incorporates a space for pipes and cables. The inventors ensure that construction and maintenance of this sustainable plastic track is faster and simpler, and the path is three times more durable than traditional roads.

The idea becomes even more interesting when you take into account rising prices of raw materials and the shortage of production capacity. An increase in the price of crude oil have affected asphalt cost, which in turn causes abnormally higher prices of construction projects, including bike roads. It also contributes to increasing fuel costs, which is certainly a reason to consider riding a bicycle to work.

Mokumono Bikes

A return to traditional craftsmanship using modern production techniques.

Did you know that as many as 97% of all bicycles sold in Europe are assembled using frames and other parts imported from factories in South-East Asia. The components travel thousands of kilometers to be gathered together at the assembly plant. Bicycle production is thus extremely vulnerable to any supply chain disruptions.

This was not always the case: the Netherlands, a country famous for its bicycles, could once take pride of being a bike manufacturer. The founders of the Mokumono brand refer to this tradition and launch lightweight and elegant e-bikes made entirely in the Netherlands. Inspired by the technique used in the automotive industry, the two brothers replaced a standard frame fabricated from steel tubes with a frame made from two identical sheets of aluminium, pressed into form and laser-welded. The production process is fully automated and relatively inexpensive, allowing the frame to be manufactured in the Netherlands.

Sellpy

An online second hand fashion shop operated in a total of 24 countries across Europe, designed to keep clothes in circulation for much longer.

According to the Less Group survey report, 69% of Poles are now open to buying second-hand clothes. There are many reasons for second-hand shopping, like affordable prices, high quality of items, vast selection and range of garment categories and last but not least, the environmental concern. The second-hand platform users believe that by opting for circular economy, they produce less waste and are not dependent on the fast fashion industry.

It comes as no surprise then that the market in used clothes is thriving and growing in popularity. Thrift fashion stores are more and more often choosing to operate online, too. Swedish online second-hand startup Sellpy was founded in 2014 and is now available to platform users in 24 European countries, including Germany, the Netherlands and Poland. The majority of its shares is owned by H&M Group. Sellpy encourages more responsible and sustainable consumer behaviour and reduction of negative environmental impact, which can be done by reusing items that have already been produced.

Sourcemap

2011

What is the distance a product must travel before it reaches the consumer?

A label "Made in..." does not clarify much, as the supply chain is an extremely complex system: very often manufacturer’s business is thousands kilometres away from the factory where the goods are made, and the distribution centre is on another continent. However, there is a way to find out where the items we buy originate from. A new online tool, Sourcemap, is offering a solution. It allows users to track the supply chain in a variety of industries: food, automotive or fashion.

Sourcemap's original goal was to spread sustainable design and supply chain transparency – the platform was designed to help measure carbon footprint or verify if the commodity suppliers were in compliance with deforestation-free policies. With the outbreak of the pandemic, logistics has become a primary concern. Supply chain mapping technology helps organizations manage supply chain, effectively prevent and reduce risk and ensure that supplies of goods are not disrupted. On Sourcemap, businesses can easily access all of their supply chain information, and verify reliability to avoid contracting suppliers which may not be able to deliver on time or in full.

Blackout emergency kit

Saving energy is a top priority for everyone these days, but not everyone knows how to prepare for long-term power outages.

Gas and coal prices are soaring, and fear of electricity shortages and blackouts is becoming increasingly real. Governments are setting out plans to help people lower household bills and reduce energy demand by improving energy management efficiency. The Dutch government has launched a campaign urging people to take shorter showers and turn down their central heating. The latter method is particularly effective – Luc Bouwens, professor of biomedical sciences from the Free University of Brussels (VUB), has calculated that turning down your thermostat by just one degree can save you about 700 € per year.

The Polish government safety agency (RCB) warns us against prolonged power outages and recommends having a survival kit on hand. A good blackout emergency kit should include a torch, candles, a first aid kit, a charged power bank and food supplies that do not require access to electricity for storage and preparation. A blanket, a few bottles of water, matches, a pocket knife and cash can also be useful.